PRODUCTS

CONTACTS

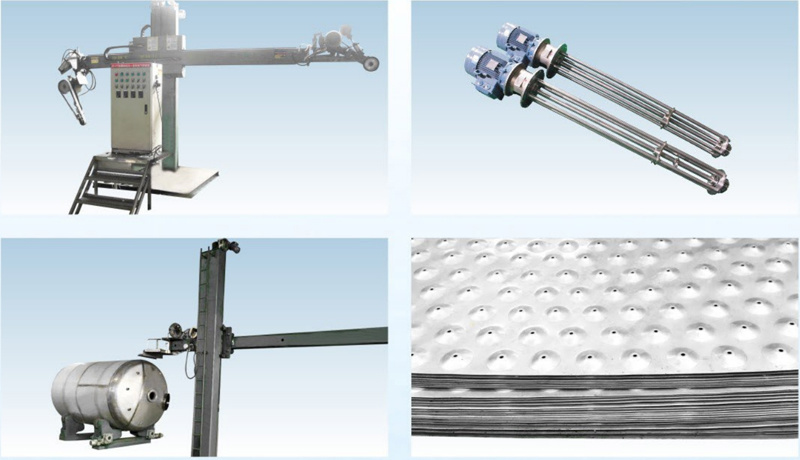

Sanitary grade stainless steel tank/Ghee processing plant

Product Detail

Brief Introduction:

a、Scraped surface heat exchanger's application in the range of soy sauce's sterilization

Soy sauce is kind of material sensitive to the heat exchanging,firstlywe adopt scrape wall heat exchanger to heat and reach the temperature of 85~90℃,and then we adopt Scraped surface heat exchanger to increase the temperature to 105~110℃ the whole heating and sterilization process is continuous and stable.The efficiency of our scraped surface heat exchanger (Unit A)is 3 to 5 times higher than other similar products, it is not only suitable for low viscosity fluid,also more suitable for high viscosity fluid or granular fluid with sensitivity to heat exchanging.

With high efficiency of heat exchange ,our equipment can achieve instant high temperature sterilization and quick cooling, and solve the problem to avoid surface charring and liquid crystallization when dealing with high viscosity materials. This equipment is most suitable for processing of margarine, shortening tomato sauce,peanut butter,chocolate,jam, dairy products,syrup,cosmeticsandetcwithaseptic packaging.

b、Scraped surface heat exchanger's application in the range ofvegetable/fruit juice's sterilization

The vegetable/fruit juice will be heated to 110~115℃ for sterilization before concentration. As fiber, protein,water are included in vegetable/fruit, it is easy to occur surface charring while heating. lt is out of normal heat exchanger's reach to fix this problem, while our equipment can achieve instant high temperature sterilization, and solve the problem to avoid surface charring and liquid crystallization when dealing with high viscosity materials..

Structure Chart:

Product Inquiry

We will contact you within one working day. Please pay attention to your email.