PRODUCTS

CONTACTS

Fully Automatic CIP Cleaning System

Product Detail

Brief Introduction:

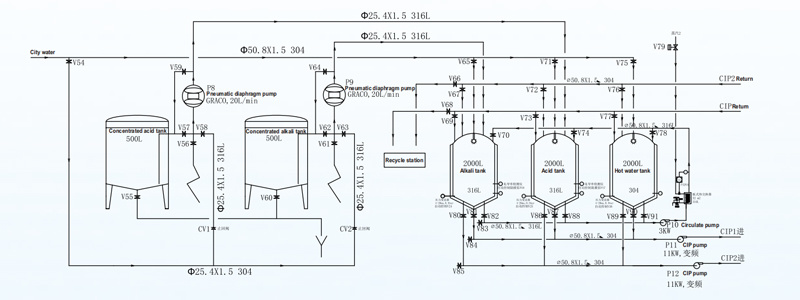

The automatic ClP cleaning system is suitable for cleaning of storage tanks, material pipelines and equipment in margarine, sauces, dairy products, beer, beverage processing plants and general food plants. The system consists of concentrated alkali tank concentrated acid tank, alkali tank, acid tank, hot water tank, centrifugal pump, plate heat exchanger, temperature control valve, pressure transmitter, conductivity meter temperature probe and PLC electrical control system, etc. lt uses the centrifugal pump to transfer the cleaning fluid to the material pipeline and equipment to achieve the purpose of circulated cleaning. Therefore, there is no need to disassemble the pipeline and equipment, which can improve the utilization rate of equipment and reduce the labor intensity of workers. The system can carry out acid washing, alkali washing, and hot water washing independently, and can also prepare a specific cleaning program for automatic cleaning according to requirements. it can not only effectively clean the equipment, but also control the growth of microorganisms; at the same time, it can work semi-automatic and fully automatic according to customers require. The concentration of acid or alkali is automatically configured according to the set conductivity, and the cleaning of the system is fully automatic. Compared with manual cleaning, it greatly reduces the cleaning time and improves work efficiency, and the use of cleaning materials and water will be more reasonable. The steam opening is automatically adjusted when it reaches the set temperature, so the steam consumption is relatively small, which can achieve the purpose of rational use of energy. Thus it can reduce the cost of cleaning effectively. The PLC control system is the accumulation of many years of experience, which makes our contro program perfect, equipped with the imported high-quality control components, ensures the ong-term and stable operation of the system. The high-end HMl can shorten the training time of operators, and display the working status of the key components of the equipment intuitively, easy to understand and operate, assist the operator to determine and deal with a variety of common fault information, so that the equipment can be restored to norma status in time. The ClP online cleaning system is cost-economic, has a compact structure and a small footprint, is easy and convenient to install and maintain, and it can clean the tank, pipeline, and equipment on the spot effectively, reducing the chance of secondary pollution since the whole cleaning process is in the closed production equipment. lt can be divided into one to four piping according to production requirements. Especially for two and more than two piping, it can not only clean the same or more than two areas at the

same time, but also clean during the production process. In this way, the time for ClP cleaning is shortened during production. The fully automatic CiP cleaning system can automatically detect, add, discharge, display and adjust the cleaning fluid. it has reliable operation, high degree of automation, simple operation, and good CiP cleaning effect, so it is more in line with the hygienic requirements and production environment requirements of modernlarge-scale fluid, medicine, and food processing techniques.

Structure Chart:

Product Inquiry

We will contact you within one working day. Please pay attention to your email.