PRODUCTS

CONTACTS

Margarine/shortening pilot plant ( lab scale)

Product Detail

Brief Introduction:

Margarine/shortening pilot plant consists of small emulsification tank, pasteurizer system, Scraped Surface Heat Exchanger, refrigerant flooded evaporative cooling system, pin worker machine, package machine, PLC and HMI control system and electrical cabinet. An optional Freon compressor is available. Every component is designed and fabricated in-house to simulate our full scale production equipment. All critical components are imported brand, including Siemens, Schneider and Parkers etc. The system could use either ammonia or Freon for chilling.

Advantages:

The advantages of our pilot plant are : complete production line, compact design, space saving, ease of operation, convenient for cleaning, experiment oriented, flexible configuration, and low energy consumption. The line is most suitable for laboratory scale experiments and R&D work in new formulation. We are one of the few companies to offer a margarine pilot plant globally.

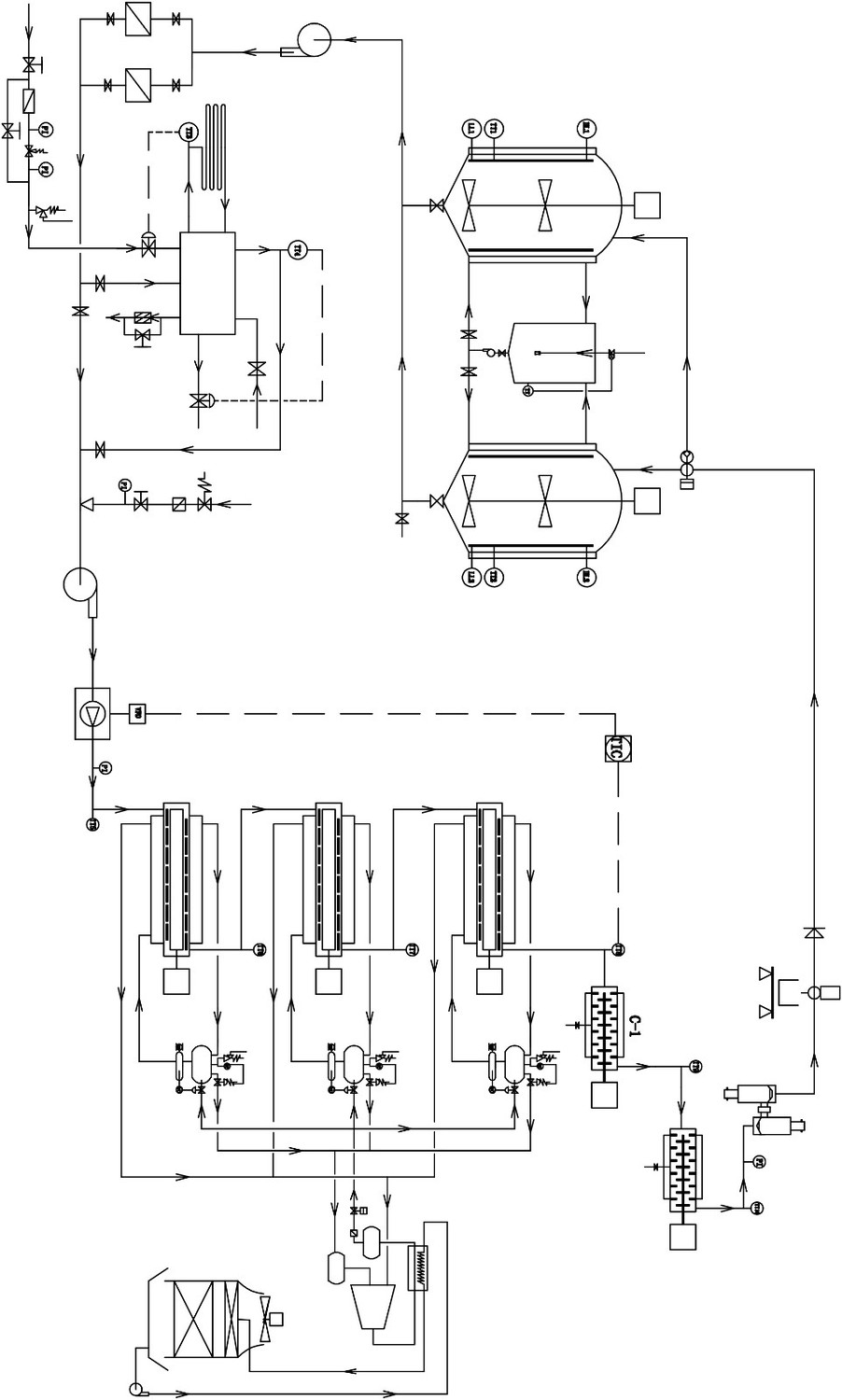

Process Flow:

Photos:

Product Inquiry

We will contact you within one working day. Please pay attention to your email.