PRODUCTS

CONTACTS

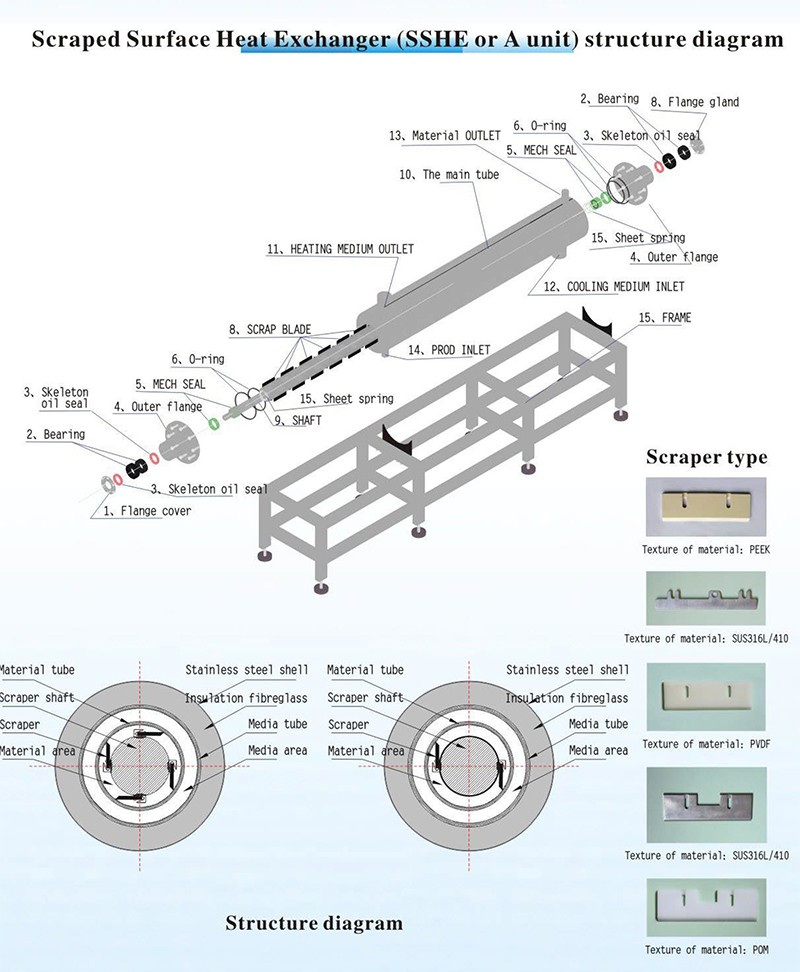

Scraped surface heat exchanger

Product Detail

Brief Introduction:

The SSHE is modeled after the votator type of heat exchanger combined with the European modifications to enhance the overall performance. It shares many interchangeable parts like bearing, mechanical seal and scrapers blades. The basic design consists of a pipe-in-pipe cylinder with inner pipe for product and outer pipe for cooling refrigerant. A rotating shaft with scrapers blades provides the necessary scraping function of heat transfer, mixing and emulsification. The SSHE could be used as a heater using steam inside the jacket or chilling using either chilled water or direct refrigerant evaporative cooling.

Each rotating shaft is concentrically mounted within the cylinder and has 4 rows of floating type scrapers blades in an optimum configuration. The shaft is direct driven by frequency controlled geared motors for flexibility. Each drive is optionally connected with a current sensing device. The current sensing device will automatically switch off the cooling in case the drive approaches current overload. This feature also protects against freeze-up.

The shafts are fitted with a rotary union to allow for the internal circulation of warm water and provision to flush mechanical seals is also included. An integral electric heater with circulation pump to service the shaft heating is included.

All product contact parts are made of stainless steel. Standard blades are made with long lasting PEEK or inexpensive POM and seal parts, 'o' rings etc., will be compatible with product. The support frame will be stainless steel SS304 square tube and no mild steel parts.

The direct evaporative cooling system features an external surge drum with liquid refrigerant level controller, sight glass, safety valve, evaporation pressure regulating valve, electronic pressure transmitter and pressure gage. The SSHE oil slurry exit temperature is directly controlled by the direct evaporative cooling system for precise process control.

Technical Data:

1. Annular Space 9 - 10mm

2. Total Heat Exchanger Area 1.1 m2

3. Max Product Tested Pressure 120 bar

4. Approximate Weight 1500 kg

5. Approx Dimensions (LxWxH) 2442 mm L x 300 mm dia

6. Required Compressor Capacity 60kw at -20°C

7. Shaft Speed, VFD drive 200 ~ 400 rpm

8. Blade Material PEEK, POM, SS

9. Shaft heating

- heater 6 kW 3 ph

- pump 0.1 kW 3 ph

Specification:

|

No. |

Item |

Parameter/material | |

|

1 |

A-A2000 |

Efective Heat Exchange Area |

1.0 square meter |

|

A-A1500 |

0.75 square meter |

||

|

A-A1000 |

0.5 square meter |

||

|

A-A2000T |

1.3 square meter |

||

|

2 |

Heat transfer capacity |

200-360 Btu/(ft ²*h*°F) |

|

|

3 |

Scraper material inner surface cleanliness |

PEEK,PVDF,PDM,SUS316L |

|

|

4 |

Material inwall fineness |

Ra≤ 0.2μm |

|

|

5 |

Material inwall 's hardness after chromplate treatment |

Rockwell hardness 85~90 |

|

|

6 |

Scraper rotor speed |

160~400 RPM |

|

|

7 |

Material cylinder seal |

Sanitary mechanical seal |

|

|

8 |

Material layer resistance to pressure |

≥ 3.0MPa |

|

|

9 |

Heat-resistantance of material layer |

-20°C-135°C |

|

|

10 |

Materials for cylinder and flange |

SUS304, SUS316L |

|

|

11 |

Connection of medium |

Welding with opening for medium |

|

|

12 |

Medium sealing of detachable inner |

"0" shape ring and PTFE gasket |

|

|

13 |

Temperature endurance of medium layer |

-40°C-180°C |

|

|

14 |

Medium layer thermal resistance |

-20°C-150°C |

|

|

15 |

Pressure endurance of medium layer |

≥ 2.0MPa |

|

|

16 |

Pressure endurance of detachable inner medium layer |

≥ 1.5MPa |

|

|

17 |

Material of inner flange and medium tank |

SUS304, SUS316L |

|

|

18 |

Insulating material |

Asbestosl,polyurethan |

|

|

19 |

Material after insulating layer |

SUS304 ( thinkness : 1.0mm) |

|

|

20 |

Material inlet |

1.5~3 inch Clip type or flange or flange |

|

|

21 |

Material outlet |

1.5~4 inchClip type or flange or flange |

|

|

22 |

Medium inlet |

2.5~3 inch flange |

|

|

23 |

Medium outlet |

2.5~3 inch flange |

|

|

24 |

Installation method |

Horizontal ,vertical |

|

|

25 |

Effective length |

A-A2000 |

2000mm |

|

A-A1500 |

1500mm |

||

|

A-A1000 |

1000mm |

||

|

A-A2000T |

2000mm |

||

|

26 |

The length of installation |

A-A2000 |

3000mm |

|

A-A1500 |

2500mm |

||

|

A-A1000 |

2000mm |

||

|

A-A2000T |

3000mm |

||

Heat Transfer Coefficient Conversion Table:

|

[J/(m2·s·K)] [W/(m2·K)] |

[kcal/(m2·h·℃)] |

[cal/(cm2·s·℃)] |

[Btu/(ft2·h·℉)] |

|

1 |

0.8598 |

2.388×10-5 |

0.1761 |

|

1.162 |

1 |

2.778×10-5 |

0.2048 |

|

4.187×104 |

3.6×104 |

1 |

7373 |

|

5.678 |

4.882 |

1.356×10-4 |

1 |

|

Note: 1W/(m2·K)=0.86 kcal/(m2·h·℃); 1kcal/(m2·h·℃)= 1.163 W/(m2·K); 1J=0.2389 cal |

|||

Construction:

Product Inquiry

We will contact you within one working day. Please pay attention to your email.